FOTO: ANP / SABINE JOOSTEN

READING TIME: 2 MINUTES

PROPOSITION

Janet Chik – Faculteit Science and Engineering

‘Uncertainty is an uncomfortable position. But certainty is an absurd one.’ (Voltaire)

A small company in Grootegast produces bicycle baskets and slippers from recycled rubber.

That is remarkable because, until recently, it was impossible to recycle rubber. However,

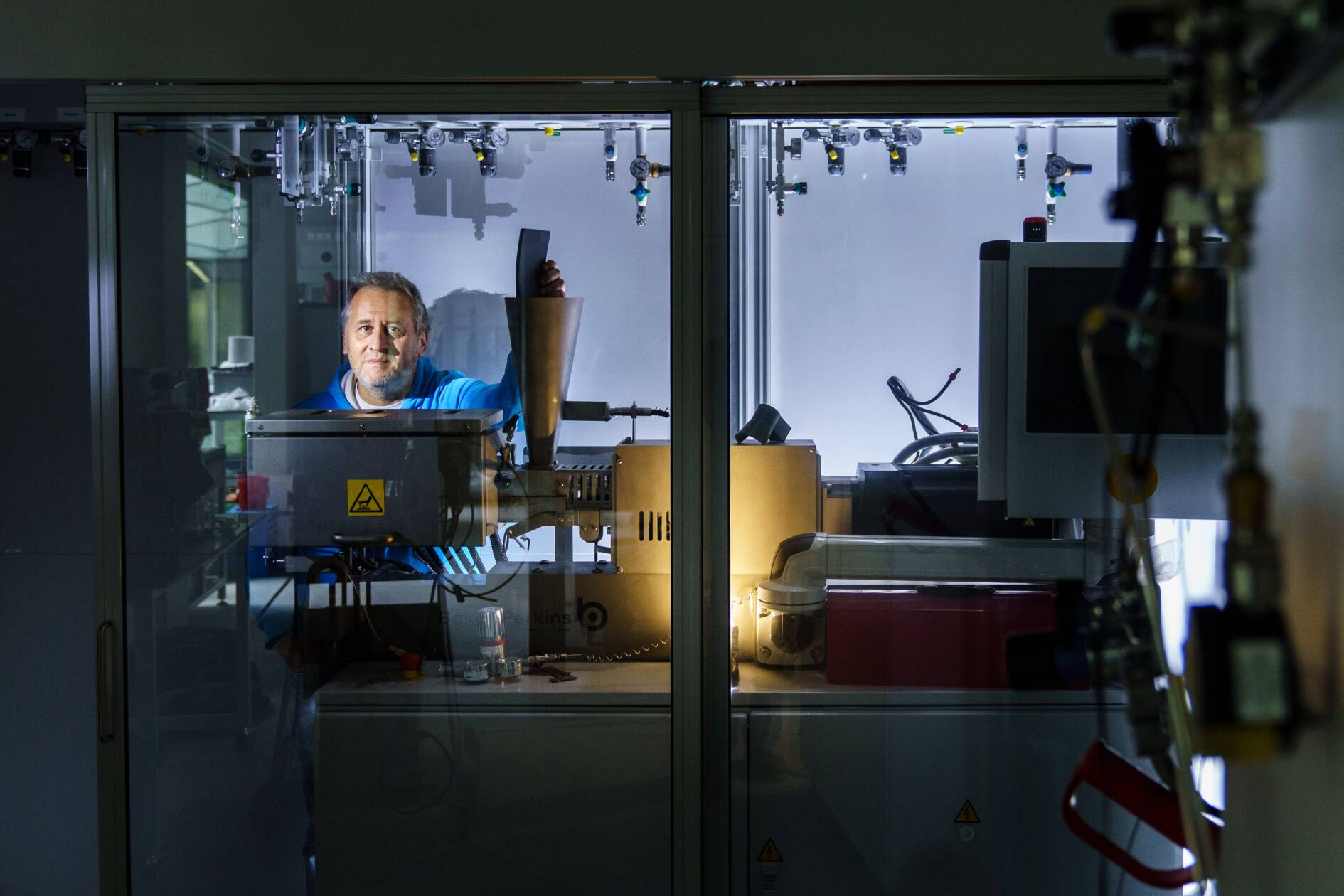

Francesco Picchioni, Professor of Chemical Technology at the University of Groningen,

and Ton Broekhuis, now Emeritus Professor, discovered how this could be done.

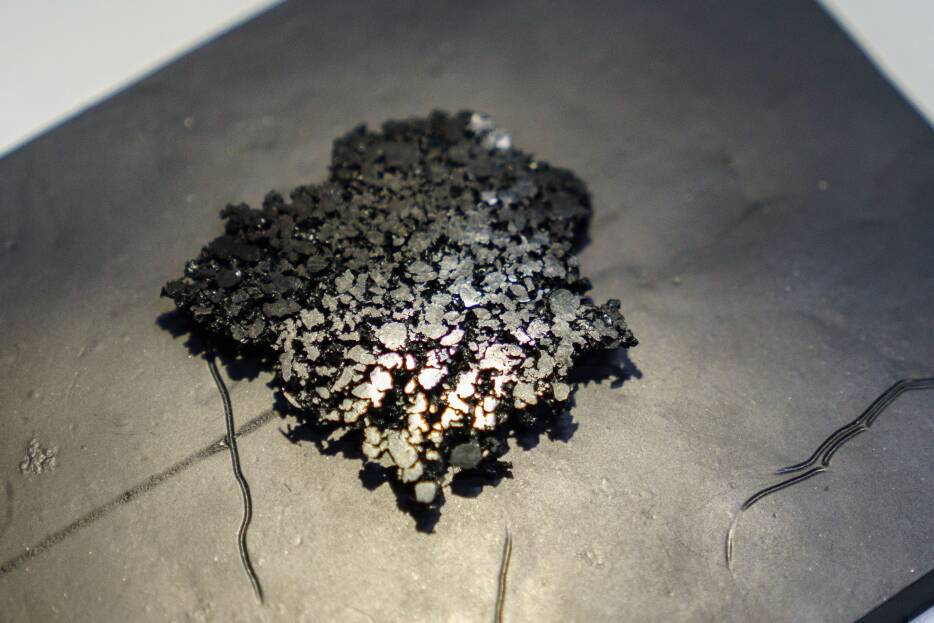

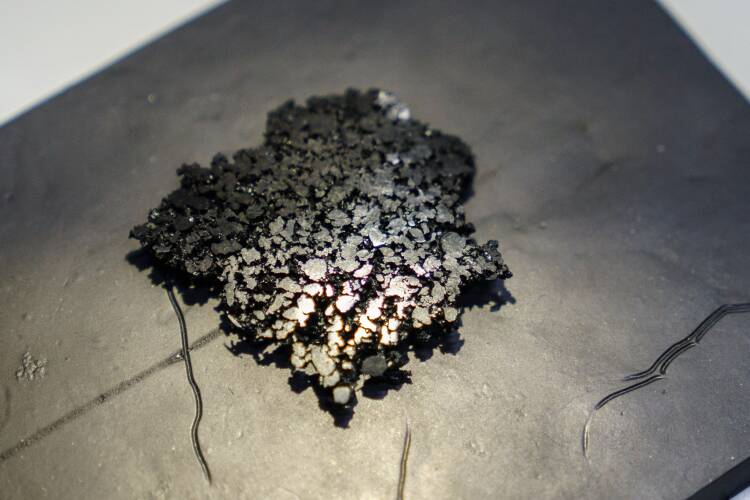

Virgin rubber, both natural and synthetic, is a sticky,

viscous fluid made up of long, spaghetti-like molecules. In the 19th century, Charles Goodyear invented a process to turn this fluid into the rubber we all know now, linking the spaghetti strings with so-called sulfur bridges, a process called vulcanization. ‘When the strings are connected in this way, their movement is limited, which turns the fluid into a stretchable solid,’ Picchioni explains.

Tricky

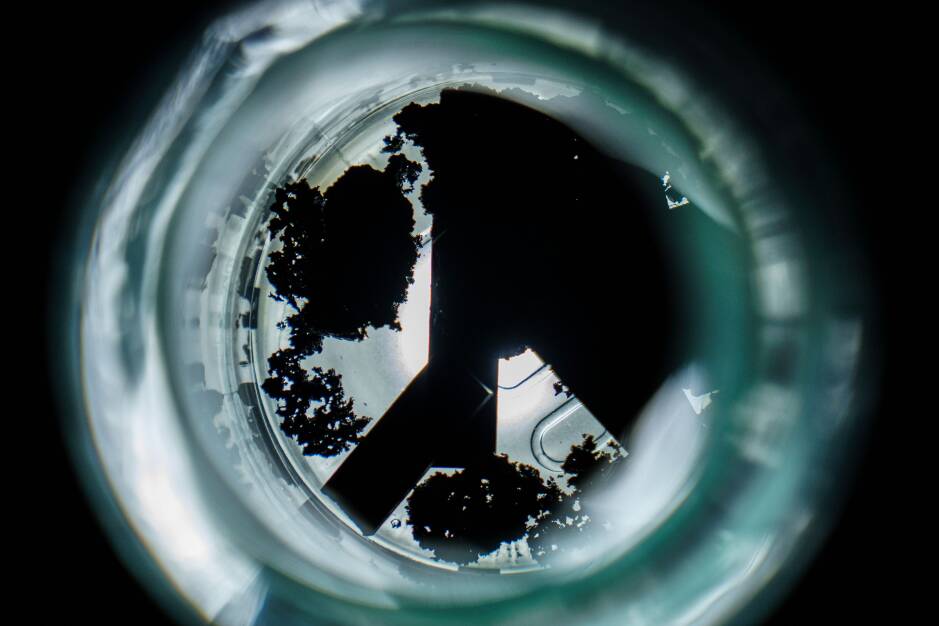

To recycle old rubber, the sulfur bridges must be broken. That is very tricky because most methods also break the spaghetti strings. This is a problem, as shorter strings result in lower-quality rubber. Therefore, scientists all over the world have been looking for a method that will break the sulfur bridges while leaving the strings mostly intact.

A contrarian

Picchioni looked at what his colleagues were doing and then decided to go in the opposite direction. ‘I’m a bit of a contrarian,’ he says. ‘If everyone turns to the right, I want to

know what happens when I turn left.’ He decided to simply

break the ‘spaghetti’ using mechanical force, which resulted in short chains. Then, he added a compound which randomly links the fragments. ‘This produces a sticky, viscous fluid which can be vulcanized, and the result is rubber of almost virgin quality.’

Patented

The patented discovery is used by New Born Rubber, a small company in Grootegast. They can already make slippers and bicycle baskets from recycled rubber. ‘I won’t make much money from this discovery, and working on it has even slightly reduced my output of scientific papers. But I have solved a real-life problem, and I’m happy with that.’

TEXT: RENÉ FRANSEN | PHOTOS: REYER BOXEM

READING TIME: 4 MINUTES

PROPOSITION

Janet Chik – Faculteit Science and Engineering

‘Uncertainty is an uncomfortable position. But certainty is an absurd one.’ (Voltaire)

Virgin rubber, both natural and synthetic, is a sticky, viscous fluid made up of long, spaghetti-like molecules. In the 19th century, Charles Goodyear invented a process to turn this fluid into the rubber we all know now, linking the spaghetti strings with so-called sulfur bridges, a process called vulcanization. ‘When the strings are connected in this way, their movement is limited, which turns the fluid into a stretchable solid,’ Picchioni explains.

Tricky

To recycle old rubber, the sulfur bridges must be broken. That is very tricky because most methods also break the spaghetti strings. This is a problem, as shorter strings result in lower-quality rubber. Therefore, scientists all over the world have been looking for a method that will break the sulfur bridges while leaving the strings mostly intact.

A contrarian

Picchioni looked at what his colleagues were doing and then decided to go in the opposite direction. ‘I’m a bit of a contrarian,’ he says. ‘If everyone turns to the right, I want to know what happens when I turn left.’ He decided to simply break the ‘spaghetti’ using mechanical force, which resulted in short chains. Then, he added a compound which randomly links the fragments. ‘This produces a sticky, viscous fluid which can be vulcanized, and the result is rubber of almost virgin quality.’

Patented

The patented discovery is used by New Born Rubber, a small company in Grootegast. They can already make slippers and bicycle baskets from recycled rubber. ‘I won’t make much money from this discovery, and working on it has even slightly reduced my output of scientific papers. But I have solved a real-life problem, and I’m happy with that.’

A small company in Grootegast produces bicycle baskets and slippers from recycled rubber. That is remarkable because, until recently, it was impossible to recycle rubber. However, Francesco Picchioni, Professor of Chemical Technology at the University of Groningen, and Ton Broekhuis, now Emeritus Professor, discovered how this could be done.

TEXT: RENÉ FRANSEN / PHOTOS: REYER BOXEM